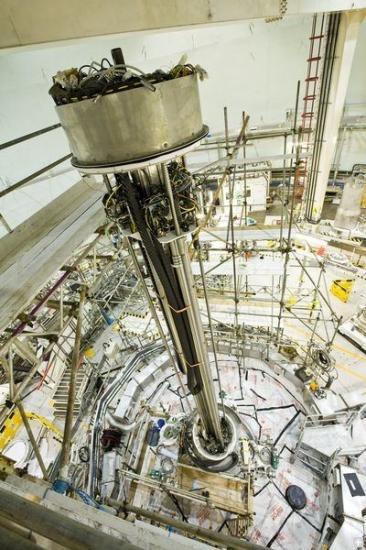

Breeder element removal tool installed in fast reactor

24th December 2008

A versatile remotely-operated machine that will cut the heart out of Dounreay's fast reactor has been installed in the sphere.

The retrieval cell is a highly engineered tool that will reach down inside the reactor vessel and remove the remaining breeder elements in a delicate and precise operation.

The retrieval cell mast towers 27ft above the floor of the sphere. It is bolted onto the top of the retrieval cell, which in turn is bolted onto the rotating shields covering the reactor. The cell houses a series of specialist tools purpose built for the removal job.

The tools will be used to remove each 8ft element from the reactor core. It is an extremely hostile environment - the highly active elements are coated with volatile liquid metal at temperatures of fifty degrees centigrade.

Many of the elements are expected to be warped and distorted or swollen, and will have to be cut out of the reactor core before they can be removed.

Once free of the core they will be lifted into a flask and transported via a transfer tube to a process cell in the adjoining containment building, where they will be dismantled, washed, and packaged for safe storage. All of these operations are conducted under a nitrogen environment to prevent NaK fires.

The retrieval cell and mast were built in Toulon, France by French nuclear experts Areva, and tested with DSRL engineers in attendance, before being shipped over to Caithness and installed in the sphere.

It is a completely bespoke tool, which project manager Peter Poulton believes is unique.

"The distortion of the breeder elements was caused during the irradiation process, and has posed a problem to their removal," he explained.

"With our input, Areva have produced a machine that is versatile enough to be able to cut away every stuck element and remove it from the core."

Retrieving the breeder elements is expected to begin in 2012, once the bulk liquid metal coolant has been destroyed, and will take an estimated two to three years to complete.

Related Businesses

Related Articles

TAE Technologies and UKAEA partner to commercialise fusion tech

Joint venture to develop neutral beams for fusion and non-fusion applications, creating high-skilled jobs and establishing a critical supply chain. TAE Technologies, a leading US private fusion energy firm with over 25 years at the forefront of scientific innovation, today announces a bilateral and reciprocal investment commitment with the United Kingdom's national fusion laboratory, the UK Atomic Energy Authority (UKAEA) to commercialise TAE's proprietary particle accelerator technology for the global market.

Buried Hazards, Unfinished Business - What the NDA's 2025 Progress Report Really Tells Us

The Nuclear Decommissioning Authority (NDA) has released its 2025 Mission Progress Report is a slightly sprawling document chronicling one of the UK's most complex environmental undertakings. The safe dismantling of its early nuclear legacy.

New recruit officers join the Civil Nuclear Constabulary

The Civil Nuclear Constabulary (CNC) welcomes its newest recruits. The CNC hosted two passing out parades for the graduating Authorised Firearms Officers (AFOs) of Initial Foundation Programme (IFP) 106.

Dounreay's next generation of talent honoured by apprentice award

Nuclear Restoration Services Dounreay's Kate Thomson has won Modern Apprentice of the Year at the Highlands & Islands Apprenticeship Awards in Inverness. Kate, who is in the second year of her apprenticeship in commercial and quantity surveying, said she was thrilled by the honour.

Taskforce calls for radical reset of nuclear regulation in UK

Nuclear Regulatory Taskforce publishes final report and calls for radical reset of overly complex nuclear regulatory system. An overly complex nuclear regulatory system has contributed to the "relative decline" of the UK's ability to deliver faster and cheaper nuclear projects.

NDA working with private developer to accelerate Chapelcross Hub

The NDA group has announced it's working with CX Power as the strategic developer to support the delivery of the green energy hub masterplan at Chapelcross. The Nuclear Decommissioning Authority (NDA) group has announced it's working with CX Power as the strategic developer to support the delivery of the green energy hub masterplan at Chapelcross, a programme set to transform the region.

Funding approved for Wick Harbour port consultant

A specialist ports consultant has been appointed to develop a long-term strategic plan for Wick Harbour Authority (WHA) in Caithness. WHA has secured £47,775 from Highlands and Islands Enterprise (HIE) and the Nuclear Restoration Services, NRS Dounreay towards the cost of the services.

NDA announces £1 million funding to accelerate clean energy in West Cumbria

NDA announces £1 million investment to develop masterplan for clean energy development on land adjacent to Sellafield. The Nuclear Decommissioning Authority (NDA) has announced today it's investing £1 million of funding to develop the masterplan for a clean energy development on land adjacent to Sellafield, known as Pioneer Park.Fallon Campbell From Melvich Near Thurso Named As Apprentice of the Year At Awards In London

Rising star from North Scotland honoured at event to celebrate brightest and best in industry. An electrical apprentice from North Scotland is celebrating after being recognised for her contribution to industry at the 13th annual Engineering Construction Industry ECI Training and Development Awards in London.

The NDA Group Graduate Programme: more than a job

The NDA group graduate scheme offers far more than just a stepping stone into the nuclear industry; it's a chance to grow professionally, explore new places, and become part of a supportive community. Nuala Ledward, Assurance and Performance Graduate, shares how her secondment to Dounreay brought these benefits to life.