Shaft clean-up nominated for top award

24th December 2008

A ground-breaking project to recover nuclear waste from a shaft beneath Dounreay is in the running for a top award.

The project team has already taken a top in-house award for its safety and environmental performance during a three-year operation to divert groundwater from the shaft.

Now, a panel of experts has nominated it for a top UK award in the technical excellence category.

The �27m shaft isolation project is one of the finalists in the 2009 Ground Engineering Awards to be announced in February.

Randall Bargelt, regional director of the Nuclear Decommissioning Authority, said: "This project delivered world-class performance in terms of its technical, budget and schedule delivery. The nomination reflects great credit on all those who made this project such an outstanding success."

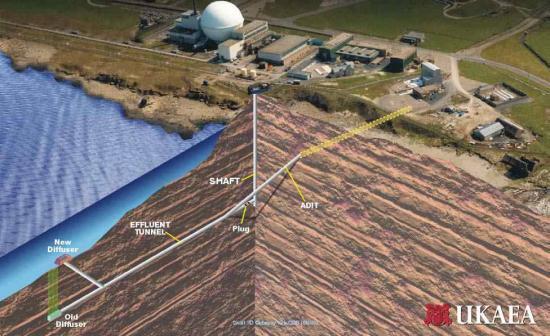

Nuclear waste was disposed of in a 65-metre deep, water-filled shaft between 1958 and 1977.

Retrieving the waste will increase the amount of groundwater that flows into the shaft and gets contaminated, so engineers looked at ways to divert the groundwater to avoid the need for a �200m water treatment plant.

Dounreay hired specialist geotechnical contractor BAM Ritchies, part of the BAM Nuttall group, to fill in the fissures in a 10-metre wide band to create a grout curtain all around the shaft.

BAM Ritchies drilled more than 300 boreholes up to 80 metres deep, stretching a combined distance of 24km.

It took four years from the start of trials to complete the isolation project in spring 2008.

A specialist grout from Sweden was ground down until it was finer than toothpaste, injected through the boreholes and squeezed into the fissures around the shaft where it hardened.

The final evaluation report just published indicates that the amount of water that can get into the shaft during waste retrieval has reduced from an estimated 350m3/day to 12.7m3/day.

Warren Jones, the Dounreay geologist in charge of the project, said: "The specification for hydraulic performance was one of the most challenging ever set.

"That lead to a very high level of team working between the client and contractor based on the new engineering contract. The results they achieved are remarkable."

Alex Tiernan, BAM Ritchies project manager for shaft isolation, said: "The degree of co-operation between client DSRL, BAM Ritchies project team, designer Halcrow and other key elements of the supply chain was crucial to the success of this four-year project. Being selected as one of the GE Awards finalists is a credit to all involved."

Work is now underway to prepare for the construction of the retrieval plant in 2012, with the first waste due to be recovered in 2017.

Related Businesses

Related Articles

TAE Technologies and UKAEA partner to commercialise fusion tech

Joint venture to develop neutral beams for fusion and non-fusion applications, creating high-skilled jobs and establishing a critical supply chain. TAE Technologies, a leading US private fusion energy firm with over 25 years at the forefront of scientific innovation, today announces a bilateral and reciprocal investment commitment with the United Kingdom's national fusion laboratory, the UK Atomic Energy Authority (UKAEA) to commercialise TAE's proprietary particle accelerator technology for the global market.

Buried Hazards, Unfinished Business - What the NDA's 2025 Progress Report Really Tells Us

The Nuclear Decommissioning Authority (NDA) has released its 2025 Mission Progress Report is a slightly sprawling document chronicling one of the UK's most complex environmental undertakings. The safe dismantling of its early nuclear legacy.

New recruit officers join the Civil Nuclear Constabulary

The Civil Nuclear Constabulary (CNC) welcomes its newest recruits. The CNC hosted two passing out parades for the graduating Authorised Firearms Officers (AFOs) of Initial Foundation Programme (IFP) 106.

Dounreay's next generation of talent honoured by apprentice award

Nuclear Restoration Services Dounreay's Kate Thomson has won Modern Apprentice of the Year at the Highlands & Islands Apprenticeship Awards in Inverness. Kate, who is in the second year of her apprenticeship in commercial and quantity surveying, said she was thrilled by the honour.

Taskforce calls for radical reset of nuclear regulation in UK

Nuclear Regulatory Taskforce publishes final report and calls for radical reset of overly complex nuclear regulatory system. An overly complex nuclear regulatory system has contributed to the "relative decline" of the UK's ability to deliver faster and cheaper nuclear projects.

Funding approved for Wick Harbour port consultant

A specialist ports consultant has been appointed to develop a long-term strategic plan for Wick Harbour Authority (WHA) in Caithness. WHA has secured £47,775 from Highlands and Islands Enterprise (HIE) and the Nuclear Restoration Services, NRS Dounreay towards the cost of the services.

Fallon Campbell From Melvich Near Thurso Named As Apprentice of the Year At Awards In London

Rising star from North Scotland honoured at event to celebrate brightest and best in industry. An electrical apprentice from North Scotland is celebrating after being recognised for her contribution to industry at the 13th annual Engineering Construction Industry ECI Training and Development Awards in London.

The NDA Group Graduate Programme: more than a job

The NDA group graduate scheme offers far more than just a stepping stone into the nuclear industry; it's a chance to grow professionally, explore new places, and become part of a supportive community. Nuala Ledward, Assurance and Performance Graduate, shares how her secondment to Dounreay brought these benefits to life.

UKAEA develops 3D printing for fusion components

At its recently opened Central Support Facility (CSF), UKAEA has commissioned an electron beam additive manufacturing machine that can be used to incorporate tungsten into components, alongside a selective laser manufacturing machine. Fusion can play a key role in a global low carbon energy future.Advancing Fusion Remote Maintenance: Industry Collaboration Driving Innovation

As part of the Fusion Futures (FF) programme, UKAEA's Remote Applications in Challenging Environments (RACE) has partnered with industry leaders to develop two groundbreaking technologies for remote maintenance in fusion energy engineering. Thanks to FF funding, industry has taken the lead in maturing UKAEA technology concepts—delivering real-world solutions that enhance operational autonomy and reduce maintenance burdens in extreme environments.