Eight-ton Fans Will Drive Fuel Plants Clean-up

21st May 2009

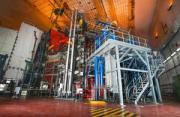

Like a giant Meccano set, some 1500 parts are being fitted together to create a new ventilation system that will protect workers decommissioning some of Dounreay's most hazardous facilities.

The network of fans, electrical infrastructure, supports, ducts, chambers and stacks will vent the airflow during the next stages of cleaning out and dismantling the key plants that made up the Fuel Cycle Area.

This was the part of the site dating from the 1950s where nuclear fuels were assembled, dissolved, examined and re-assembled in support of Britain's research and development of nuclear energy.

Decommissioning the Fuel Cycle Area is expected to cost �550 million and involves dismantling sealed facilities that are contaminated with some of the most hazardous radioactive debris.

Some of these plants have already been cleaned out and one, the former fuel fabrication plant, has been demolished - the first plant of its type ever successfully decommissioned in Scotland.

The installation of a modern ventilation system will allow teams of decommissioning staff to complete the clean-out and demolish the rest of the facilities by 2025.

The steelwork, weighing some 300 tonnes in total, was delivered to the site in pre-fabricated sections in 150 lorry-loads and installation is now almost 90 per cent complete.

The main contractor is JGC Engineering and Technical Services, with a team of about 40 people now working on the �9 million project.

"We're on schedule to inactively commission the system by the end of October," said project manager Iain Lyall of Dounreay Site Restoration Ltd. "This will be followed by a period of testing, with a target of the end of March 2010 to complete active commissioning."

Each of the dozen buildings that make up the heart of the Fuel Cycle Area has its own extract ventilation system with high integrity fans and ductwork, extracting contaminated air through high efficiency filters and exhausting into common ducts which terminate in the existing 55m high, 4.5m diameter vent stack.

By next March, the existing stack will have been replaced by a new system comprising two 30m high vent stacks, each 2m in diameter, fed by duty/standby inverter-driven 90kW & 132kW fans connected to the existing common ducts. The variable duty provided by inverter control will meet the decreasing ventilation needs as the facilities are demolished sequentially over the coming years.

Halifax Fans, West Yorkshire, supplied the four fans which, at 69 ins and 78 ins impeller diameters and weighing 8.5 tonnes each, were the largest nuclear specification gas-tight fans ever built by the company.

The fan impeller design was based upon Halifax's Beaufort fans, with self-cleaning backward curved impellers which can be withdrawn from the drive side so that should it prove necessary, this can be achieved without the need to disconnect any ductwork. The exterior steelwork was shot blasted and painted with a high integrity offshore/chemical works 3-coat paint system with a minimum dry film thickness of 220�m. The fans were fitted with rotation sensors and vibration monitoring equipment along with gas-tight EPDM rubber flexible connections on the fan inlets and outlets and each unit was supported on anti-vibration mounts. Following fabrication, all four fans were pneumatically pressure tested in-house and witness run-tested prior to despatch to site.

Related Businesses

Related Articles

TAE Technologies and UKAEA partner to commercialise fusion tech

Joint venture to develop neutral beams for fusion and non-fusion applications, creating high-skilled jobs and establishing a critical supply chain. TAE Technologies, a leading US private fusion energy firm with over 25 years at the forefront of scientific innovation, today announces a bilateral and reciprocal investment commitment with the United Kingdom's national fusion laboratory, the UK Atomic Energy Authority (UKAEA) to commercialise TAE's proprietary particle accelerator technology for the global market.

Buried Hazards, Unfinished Business - What the NDA's 2025 Progress Report Really Tells Us

The Nuclear Decommissioning Authority (NDA) has released its 2025 Mission Progress Report is a slightly sprawling document chronicling one of the UK's most complex environmental undertakings. The safe dismantling of its early nuclear legacy.

New recruit officers join the Civil Nuclear Constabulary

The Civil Nuclear Constabulary (CNC) welcomes its newest recruits. The CNC hosted two passing out parades for the graduating Authorised Firearms Officers (AFOs) of Initial Foundation Programme (IFP) 106.

Dounreay's next generation of talent honoured by apprentice award

Nuclear Restoration Services Dounreay's Kate Thomson has won Modern Apprentice of the Year at the Highlands & Islands Apprenticeship Awards in Inverness. Kate, who is in the second year of her apprenticeship in commercial and quantity surveying, said she was thrilled by the honour.

Taskforce calls for radical reset of nuclear regulation in UK

Nuclear Regulatory Taskforce publishes final report and calls for radical reset of overly complex nuclear regulatory system. An overly complex nuclear regulatory system has contributed to the "relative decline" of the UK's ability to deliver faster and cheaper nuclear projects.

Funding approved for Wick Harbour port consultant

A specialist ports consultant has been appointed to develop a long-term strategic plan for Wick Harbour Authority (WHA) in Caithness. WHA has secured £47,775 from Highlands and Islands Enterprise (HIE) and the Nuclear Restoration Services, NRS Dounreay towards the cost of the services.

Fallon Campbell From Melvich Near Thurso Named As Apprentice of the Year At Awards In London

Rising star from North Scotland honoured at event to celebrate brightest and best in industry. An electrical apprentice from North Scotland is celebrating after being recognised for her contribution to industry at the 13th annual Engineering Construction Industry ECI Training and Development Awards in London.

The NDA Group Graduate Programme: more than a job

The NDA group graduate scheme offers far more than just a stepping stone into the nuclear industry; it's a chance to grow professionally, explore new places, and become part of a supportive community. Nuala Ledward, Assurance and Performance Graduate, shares how her secondment to Dounreay brought these benefits to life.

UKAEA develops 3D printing for fusion components

At its recently opened Central Support Facility (CSF), UKAEA has commissioned an electron beam additive manufacturing machine that can be used to incorporate tungsten into components, alongside a selective laser manufacturing machine. Fusion can play a key role in a global low carbon energy future.Advancing Fusion Remote Maintenance: Industry Collaboration Driving Innovation

As part of the Fusion Futures (FF) programme, UKAEA's Remote Applications in Challenging Environments (RACE) has partnered with industry leaders to develop two groundbreaking technologies for remote maintenance in fusion energy engineering. Thanks to FF funding, industry has taken the lead in maturing UKAEA technology concepts—delivering real-world solutions that enhance operational autonomy and reduce maintenance burdens in extreme environments.