Fast breeder was Britain's 'man on the moon moment'

9th November 2009

It was Britain's man-on-the-moon moment, when a decade of scientific and engineering breakthroughs culminated in the most advanced nuclear plant in the world.

A workforce of 3000 had laboured around the clock for four years to build the experimental plant that would pave the way for electricity "too cheap to meter".

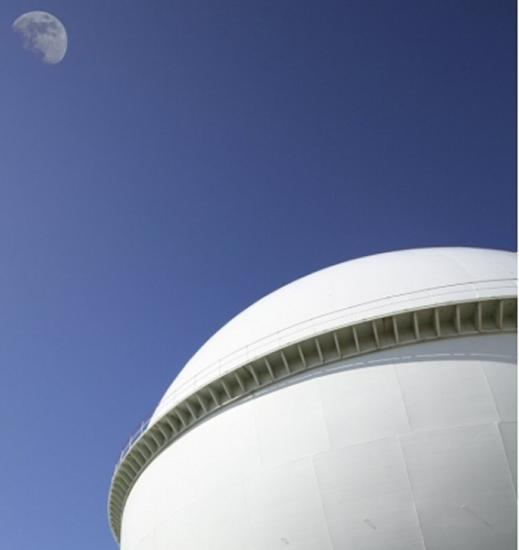

Then, on November 14, 1959, the lifeless hulk of vessels, valves and pipes installed inside the biggest steel ball ever seen in Britain started its slow heartbeat.

The moment of criticality inside the Dounreay Fast Reactor gave birth to a "caged tiger", in the words of Chapman Pincher in the Daily Express.

And it raised the hopes of a nation seeking new sources of energy. Experts believed every town in the country could be powered by its own fast reactor within 20 years.

But a series of non-nuclear faults would plague the research programme in the 1970s, Chernobyl and health concerns undermined public confidence in the 1980s, and the cost of plutonium and a glut of uranium worldwide signaled the end in the early 1990s.

Today, fifty years after that historic breakthrough, the heartbeat of Britain's first fast breeder reactor is dying - it's decommissioning and dismantling now one of the country's most important nuclear clean-up jobs.

"What Britain did in the 1950s was every bit as impressive, if not more so, than what NASA did in the 1960s. This was Britain's man-on-the-moon moment, if not better," said Mike Brown, the engineer in charge of decommissioning Dounreay's two fast reactors.

"From the creation of a design committee in 1951, Britain had delivered a working fast reactor by the end of the decade, with some big gaps in our knowledge. Those gaps were filled only with experimentation.

"Putting a man on the moon was the next step in a rocket programme that was already into space. Designing, building and operating a fast reactor from scratch, at a time when knowledge and resources were so scarce, I believe was an even bigger accomplishment. What they achieved here in the 1950s was phenomenal."

In the 1950s, fast breeder reactors were seen as a more efficient way to harness the energy contained in uranium.

The fuel in the core could be burned much more intensely and some of the energy released could be captured to "breed" a new fuel - plutonium - from an otherwise useless form of uranium that was packed around the core.

But the reaction was so intense that pressurised water or gas - the normal medium for removing the heat from a nuclear reactor - wasn't up to the task. The scientists used liquid metal instead.

Almost 170,000 litres of a sodium and potassium alloy, known as NaK, were poured into the experimental fast reactor at Dounreay. It was very effective at rapid transfer of intense heat. But the downside was its chemical hazard - the noxious alloy poses a serious risk to health and would ignite easily if mishandled.

What remains of this once-pioneering system is regarded today as one of the biggest hazards in the UK. Its destruction is second only to an old fuel facility at Sellafield in the priorities of the Nuclear Decommissioning Authority and is one of the strategic objectives of the UK's Department of Energy and Climate Change.

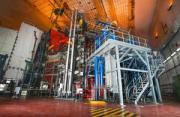

More than two-thirds of the NaK has been destroyed so far. The 47,000 litres that remain are heavily contaminated with radioactive caesium, so it is being scrubbed clean using an ion exchange resin as part of the destruction process. All of it should be destroyed by 2013.

When the liquid metal has gone, almost 1000 "breeder" elements positioned around the core will be exposed. These will be coated with residues of NaK. Their removal, cleaning and dismantling, using long robotic tools, will take another two years to complete.

The removal of all the liquid metal and nuclear material will leave an empty structure that can be dismantled. But radiation levels will still be too high for workers to do this manually, so much of the dismantling work will be done using robots. By 2025, when the entire structure has been dismantled, the total decommissioning bill is expected to be �240 million.

Related Businesses

Related Articles

TAE Technologies and UKAEA partner to commercialise fusion tech

Joint venture to develop neutral beams for fusion and non-fusion applications, creating high-skilled jobs and establishing a critical supply chain. TAE Technologies, a leading US private fusion energy firm with over 25 years at the forefront of scientific innovation, today announces a bilateral and reciprocal investment commitment with the United Kingdom's national fusion laboratory, the UK Atomic Energy Authority (UKAEA) to commercialise TAE's proprietary particle accelerator technology for the global market.

Buried Hazards, Unfinished Business - What the NDA's 2025 Progress Report Really Tells Us

The Nuclear Decommissioning Authority (NDA) has released its 2025 Mission Progress Report is a slightly sprawling document chronicling one of the UK's most complex environmental undertakings. The safe dismantling of its early nuclear legacy.

New recruit officers join the Civil Nuclear Constabulary

The Civil Nuclear Constabulary (CNC) welcomes its newest recruits. The CNC hosted two passing out parades for the graduating Authorised Firearms Officers (AFOs) of Initial Foundation Programme (IFP) 106.

Dounreay's next generation of talent honoured by apprentice award

Nuclear Restoration Services Dounreay's Kate Thomson has won Modern Apprentice of the Year at the Highlands & Islands Apprenticeship Awards in Inverness. Kate, who is in the second year of her apprenticeship in commercial and quantity surveying, said she was thrilled by the honour.

Taskforce calls for radical reset of nuclear regulation in UK

Nuclear Regulatory Taskforce publishes final report and calls for radical reset of overly complex nuclear regulatory system. An overly complex nuclear regulatory system has contributed to the "relative decline" of the UK's ability to deliver faster and cheaper nuclear projects.

Funding approved for Wick Harbour port consultant

A specialist ports consultant has been appointed to develop a long-term strategic plan for Wick Harbour Authority (WHA) in Caithness. WHA has secured £47,775 from Highlands and Islands Enterprise (HIE) and the Nuclear Restoration Services, NRS Dounreay towards the cost of the services.

Fallon Campbell From Melvich Near Thurso Named As Apprentice of the Year At Awards In London

Rising star from North Scotland honoured at event to celebrate brightest and best in industry. An electrical apprentice from North Scotland is celebrating after being recognised for her contribution to industry at the 13th annual Engineering Construction Industry ECI Training and Development Awards in London.

The NDA Group Graduate Programme: more than a job

The NDA group graduate scheme offers far more than just a stepping stone into the nuclear industry; it's a chance to grow professionally, explore new places, and become part of a supportive community. Nuala Ledward, Assurance and Performance Graduate, shares how her secondment to Dounreay brought these benefits to life.

UKAEA develops 3D printing for fusion components

At its recently opened Central Support Facility (CSF), UKAEA has commissioned an electron beam additive manufacturing machine that can be used to incorporate tungsten into components, alongside a selective laser manufacturing machine. Fusion can play a key role in a global low carbon energy future.Advancing Fusion Remote Maintenance: Industry Collaboration Driving Innovation

As part of the Fusion Futures (FF) programme, UKAEA's Remote Applications in Challenging Environments (RACE) has partnered with industry leaders to develop two groundbreaking technologies for remote maintenance in fusion energy engineering. Thanks to FF funding, industry has taken the lead in maturing UKAEA technology concepts—delivering real-world solutions that enhance operational autonomy and reduce maintenance burdens in extreme environments.