Orbital Welder For Dounreay Tested In New Facility At Bower

23rd April 2009

Dropping a large three metre stainless steel container from a great height might seem like a bizarre concept, but it's all in a days work for the PFR project team.

Storage of the spent fuel from the former fast reactor needs to be safeguarded from all potentially hazardous conditions. In order to prove the robustness of the 100kg container a replica model was subjected to a computerised simulated drop followed by an actual six and a half metre drop in the new NES Engineering Ltd off-site test facility at Bower in Caithness.

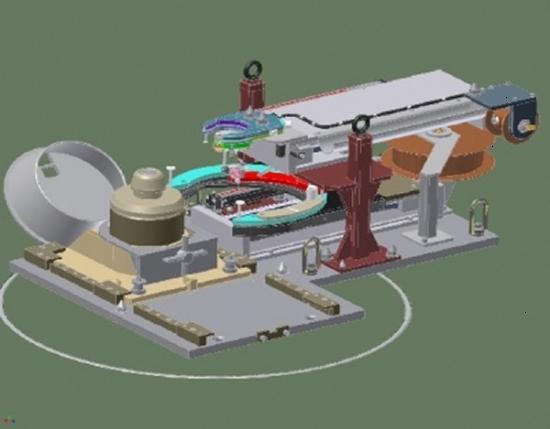

This phase of the project also included the design and manufacture of a unique remote orbital welding system adapted to remotely seal the container lids from within the PFR caves and to leak test the weld to ensure the container is fully sealed.

The �400k contract was awarded to Nuvia who subcontracted the manufacture and testing of the containers to local firm NES Engineering Ltd, who also manufactured the orbital welding equipment.

"Managing the fuel legacy safely and securely on behalf of the Nuclear Decommissioning Authority is a crucial part of the site closure programme," explained Simon Coles, PFR decommissioning manager.

"These containers and associated equipment are vital to the fuel strategy for the Dounreay site and for the decommissioning of PFR. The project was delivered to time and cost, which is a credit to the team and all contractors involved."

On completion of the tests the equipment will be shipped to Dounreay for mounting in the reactor hall cave mock up. Remote assembly trials will be carried out on the welding station to ensure it can be assembled within the confined cave environment and to train operators to use the equipment in safe and clean surroundings.

The irradiated fuel will be packaged into the new containers for long-term storage and held in an on-site facility pending a decision for re-use or management elsewhere.

Dounreay will require anywhere from two hundred to one thousand of these fuel storage containers during the decommissioning of the site.

Diagram shows a 3D image of the Remote Orbital Welding System (ROWS) as it will appear in the IFC, showing an irradiated fuel container in place ready for welding

Related Businesses

Related Articles

TAE Technologies and UKAEA partner to commercialise fusion tech

Joint venture to develop neutral beams for fusion and non-fusion applications, creating high-skilled jobs and establishing a critical supply chain. TAE Technologies, a leading US private fusion energy firm with over 25 years at the forefront of scientific innovation, today announces a bilateral and reciprocal investment commitment with the United Kingdom's national fusion laboratory, the UK Atomic Energy Authority (UKAEA) to commercialise TAE's proprietary particle accelerator technology for the global market.

Buried Hazards, Unfinished Business - What the NDA's 2025 Progress Report Really Tells Us

The Nuclear Decommissioning Authority (NDA) has released its 2025 Mission Progress Report is a slightly sprawling document chronicling one of the UK's most complex environmental undertakings. The safe dismantling of its early nuclear legacy.

New recruit officers join the Civil Nuclear Constabulary

The Civil Nuclear Constabulary (CNC) welcomes its newest recruits. The CNC hosted two passing out parades for the graduating Authorised Firearms Officers (AFOs) of Initial Foundation Programme (IFP) 106.

Dounreay's next generation of talent honoured by apprentice award

Nuclear Restoration Services Dounreay's Kate Thomson has won Modern Apprentice of the Year at the Highlands & Islands Apprenticeship Awards in Inverness. Kate, who is in the second year of her apprenticeship in commercial and quantity surveying, said she was thrilled by the honour.

Taskforce calls for radical reset of nuclear regulation in UK

Nuclear Regulatory Taskforce publishes final report and calls for radical reset of overly complex nuclear regulatory system. An overly complex nuclear regulatory system has contributed to the "relative decline" of the UK's ability to deliver faster and cheaper nuclear projects.

Funding approved for Wick Harbour port consultant

A specialist ports consultant has been appointed to develop a long-term strategic plan for Wick Harbour Authority (WHA) in Caithness. WHA has secured £47,775 from Highlands and Islands Enterprise (HIE) and the Nuclear Restoration Services, NRS Dounreay towards the cost of the services.

Fallon Campbell From Melvich Near Thurso Named As Apprentice of the Year At Awards In London

Rising star from North Scotland honoured at event to celebrate brightest and best in industry. An electrical apprentice from North Scotland is celebrating after being recognised for her contribution to industry at the 13th annual Engineering Construction Industry ECI Training and Development Awards in London.

The NDA Group Graduate Programme: more than a job

The NDA group graduate scheme offers far more than just a stepping stone into the nuclear industry; it's a chance to grow professionally, explore new places, and become part of a supportive community. Nuala Ledward, Assurance and Performance Graduate, shares how her secondment to Dounreay brought these benefits to life.

UKAEA develops 3D printing for fusion components

At its recently opened Central Support Facility (CSF), UKAEA has commissioned an electron beam additive manufacturing machine that can be used to incorporate tungsten into components, alongside a selective laser manufacturing machine. Fusion can play a key role in a global low carbon energy future.Advancing Fusion Remote Maintenance: Industry Collaboration Driving Innovation

As part of the Fusion Futures (FF) programme, UKAEA's Remote Applications in Challenging Environments (RACE) has partnered with industry leaders to develop two groundbreaking technologies for remote maintenance in fusion energy engineering. Thanks to FF funding, industry has taken the lead in maturing UKAEA technology concepts—delivering real-world solutions that enhance operational autonomy and reduce maintenance burdens in extreme environments.