Robots to rip out reactor core

24th September 2015

A range of unusual devices have been designed and built by Dounreay's in-house design team over the years.

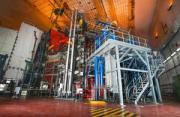

Probing the depths of a former nuclear reactor with remotely controlled equipment isn't a simple process and requires some ingenious thinking.

A Dounreay senior design engineer, who has worked on site since before PFR was built, is now part of the PFR design team responsible for safely dismantling the reactor. Together they have donned their thinking caps and pondered the unique challenges they face.

Calder Bain, a key member of the team who started life as a young Dounreay apprentice in the early 1960’s, explained: "A considerable amount of innovation was required to build the Prototype Fast Reactor and there will be a continual requirement for pioneering methods to take a reactor of this complexity apart. This type of work gives both our young and experienced engineers the opportunity to put their innovative skills and knowledge into practice."

The team has designed a series of tools which will allow the removal of hundreds of components from the reactor vessel. A total of eight multi-purpose grabbing, cutting, slicing and lifting tools are being designed and tested to pull out the core of the redundant fast reactor.

All the tools have in-built cameras fitted and are designed to operate within an extremely hazardous environment to allow safe remote operation, including plunging over 10 metres into the centre of the core to cut and remove components.

Calder is sharing his knowledge with a team of DSRL engineers to pass on his years of experience and expertise to a new generation of design professionals who will be taking apart the reactor when the time comes.

Talking about his work on the site, Calder explained: "These engineers are demonstrating huge potential and are very capable and enthusiastic young Dounreay workers who will be at the forefront of the final stages of the PFR reactor dismantling programme."

Ken Heider, project director for reactors said: “The reactor dismantling project is critical to the decommissioning of PFR. We need to use lateral thinking and unique ideas to design and build the necessary equipment to safely take apart the plant and remove the reactor vessel. The design of purpose built equipment like this is a credit to all DSRL staff and contractors involved.”

Related Businesses

Related Articles

TAE Technologies and UKAEA partner to commercialise fusion tech

Joint venture to develop neutral beams for fusion and non-fusion applications, creating high-skilled jobs and establishing a critical supply chain. TAE Technologies, a leading US private fusion energy firm with over 25 years at the forefront of scientific innovation, today announces a bilateral and reciprocal investment commitment with the United Kingdom's national fusion laboratory, the UK Atomic Energy Authority (UKAEA) to commercialise TAE's proprietary particle accelerator technology for the global market.

Buried Hazards, Unfinished Business - What the NDA's 2025 Progress Report Really Tells Us

The Nuclear Decommissioning Authority (NDA) has released its 2025 Mission Progress Report is a slightly sprawling document chronicling one of the UK's most complex environmental undertakings. The safe dismantling of its early nuclear legacy.

New recruit officers join the Civil Nuclear Constabulary

The Civil Nuclear Constabulary (CNC) welcomes its newest recruits. The CNC hosted two passing out parades for the graduating Authorised Firearms Officers (AFOs) of Initial Foundation Programme (IFP) 106.

Dounreay's next generation of talent honoured by apprentice award

Nuclear Restoration Services Dounreay's Kate Thomson has won Modern Apprentice of the Year at the Highlands & Islands Apprenticeship Awards in Inverness. Kate, who is in the second year of her apprenticeship in commercial and quantity surveying, said she was thrilled by the honour.

Taskforce calls for radical reset of nuclear regulation in UK

Nuclear Regulatory Taskforce publishes final report and calls for radical reset of overly complex nuclear regulatory system. An overly complex nuclear regulatory system has contributed to the "relative decline" of the UK's ability to deliver faster and cheaper nuclear projects.

Funding approved for Wick Harbour port consultant

A specialist ports consultant has been appointed to develop a long-term strategic plan for Wick Harbour Authority (WHA) in Caithness. WHA has secured £47,775 from Highlands and Islands Enterprise (HIE) and the Nuclear Restoration Services, NRS Dounreay towards the cost of the services.

Fallon Campbell From Melvich Near Thurso Named As Apprentice of the Year At Awards In London

Rising star from North Scotland honoured at event to celebrate brightest and best in industry. An electrical apprentice from North Scotland is celebrating after being recognised for her contribution to industry at the 13th annual Engineering Construction Industry ECI Training and Development Awards in London.

The NDA Group Graduate Programme: more than a job

The NDA group graduate scheme offers far more than just a stepping stone into the nuclear industry; it's a chance to grow professionally, explore new places, and become part of a supportive community. Nuala Ledward, Assurance and Performance Graduate, shares how her secondment to Dounreay brought these benefits to life.

UKAEA develops 3D printing for fusion components

At its recently opened Central Support Facility (CSF), UKAEA has commissioned an electron beam additive manufacturing machine that can be used to incorporate tungsten into components, alongside a selective laser manufacturing machine. Fusion can play a key role in a global low carbon energy future.Advancing Fusion Remote Maintenance: Industry Collaboration Driving Innovation

As part of the Fusion Futures (FF) programme, UKAEA's Remote Applications in Challenging Environments (RACE) has partnered with industry leaders to develop two groundbreaking technologies for remote maintenance in fusion energy engineering. Thanks to FF funding, industry has taken the lead in maturing UKAEA technology concepts—delivering real-world solutions that enhance operational autonomy and reduce maintenance burdens in extreme environments.